Paint Bucket DWC

grizzman

15 years ago

Related Stories

DECORATING GUIDES10 Design Ideas From the Bucket Section of the Hardware Store

These hardworking home essentials will add character galore and keep clutter at bay in modern-rustic style

Full Story

BARN HOMESOn an Architect's Bucket List: To Live in a Barn

Barn renovations celebrate the comfort of simple, big shapes, tied to the land

Full Story

PAINTINGWhat to Know About Milk Paint and Chalk Paint — and How to Use Them

Learn the pros, cons, cost and more for these two easy-to-use paints that are great for giving furniture a vintage look

Full Story

DECORATING GUIDES20 Bathroom Wallpapers That Bring the Wow

These spirited wallcoverings will add a drop of whimsy and a whole bucket of bold to your water closet

Full Story

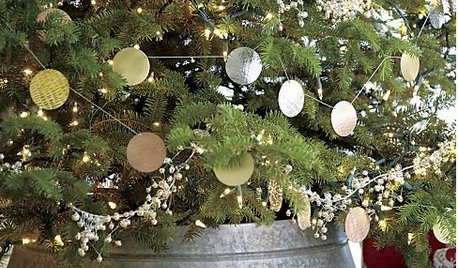

PRODUCT PICKSGuest Picks: Cool Alternatives to Christmas Tree Skirts

Give your tree a fashionable new outfit for Christmas this year with one of these collars, cuffs, baskets or buckets

Full Story

COLORCreate a Stir With Paint

Sure, you could whisk up an accent wall and call it a day. But for truly sublime rooms, brush up on these creative paint ideas

Full Story

PAINTINGBulletproof Decorating: How to Pick the Right Kind of Paint

Choose a paint with some heft and a little sheen for walls and ceilings with long-lasting good looks. Here are some getting-started tips

Full Story

PAINTINGKnotty to Nice: Painted Wood Paneling Lightens a Room's Look

Children ran from the scary dark walls in this spare room, but white paint and new flooring put fears and style travesties to rest

Full Story

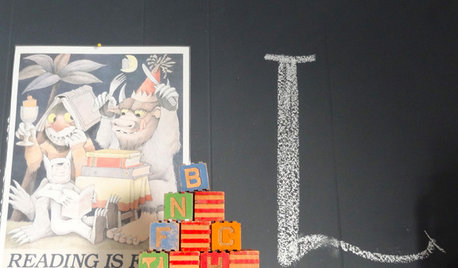

DECORATING GUIDESDIY: Make Your Own Chalkboard Paint

3 simple steps to chalk it up in any color anywhere for cheap

Full Story

FLOORSHow to Paint Your Hardwood Floors

Know how to apply nail polish? Then you can give your wooden floors a brand-new look

Full StorySponsored

Custom Craftsmanship & Construction Solutions in Franklin County

More Discussions

grizzmanOriginal Author

garysgarden

Related Professionals

McKinney Landscape Contractors · Tempe Landscape Contractors · Wakefield Landscape Contractors · Brooklyn Park Landscape Contractors · Cockeysville Landscape Contractors · Downey Landscape Contractors · El Mirage Landscape Contractors · Harvey Landscape Contractors · Kearny Landscape Contractors · Longview Landscape Contractors · Middle River Landscape Contractors · Midland Landscape Contractors · West Chicago Landscape Contractors · Westford Landscape Contractors · North Bellport Outdoor Lighting & Audio Visual SystemsgrizzmanOriginal Author

chuck

grizzmanOriginal Author

chuck

grizzmanOriginal Author

chuck

grizzmanOriginal Author

chuck

grizzmanOriginal Author

garysgarden