Krylon paint reflective values

PupillaCharites

10 years ago

Related Stories

SELLING YOUR HOUSE10 Ways to Boost Your Home's Resale Value

Figure out which renovations will pay off, and you'll have more money in your pocket when that 'Sold' sign is hung

Full Story

MOST POPULAR5 Remodels That Make Good Resale Value Sense — and 5 That Don’t

Find out which projects offer the best return on your investment dollars

Full Story

GREEN BUILDINGInsulation Basics: Heat, R-Value and the Building Envelope

Learn how heat moves through a home and the materials that can stop it, to make sure your insulation is as effective as you think

Full Story

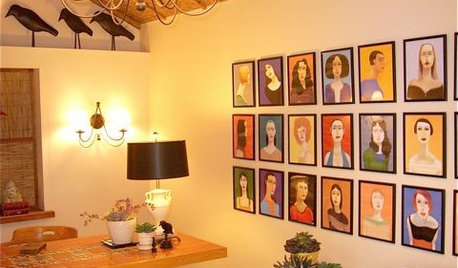

DECORATING GUIDESExpert Talk: Portraits Take Rooms Beyond Face Value

Adding depth and intrigue, portraits also sit well with these pro designers for putting a personal stamp on interior designs

Full Story

LIFE8 Ways to Tailor Your Home for You, Not Resale

Planning to stay put for a few years? Forget resale value and design your home for the way you live

Full Story

DECORATING GUIDESGet the Scoop on Finding the Best Paint for Your Money

Scoring the best deal on paint for your home may have nothing to do with advertised specials

Full Story

HOUZZ TOURSHouzz Tour: Modern Warmth for a Lake Superior Getaway

Wood and glass aplenty help a lakeside vacation home reflect its surroundings while opening to the view

Full Story

HOLIDAYSShine Up Your Holidays With DIY Mercury Glass Globes

Get expensive-looking decorations for the cost of paint and glass, with blinged-out orbs you can make at home

Full Story

WHITEWhat to Know Before You Paint Your Walls White

A coat of white paint can do wonders in one room and wreak havoc in another. Here are tips for using the popular hue

Full Story

MOST POPULARThe Right Way to Test Paint Colors

Here are 5 key steps to take to ensure you're happy with your wall paint color

Full StoryMore Discussions

cole_robbie

PupillaCharitesOriginal Author

Related Professionals

Folsom Landscape Architects & Landscape Designers · Wheeling Landscape Architects & Landscape Designers · Aurora Landscape Contractors · Elgin Landscape Contractors · Williamsburg Landscape Contractors · Fair Lawn Landscape Contractors · Fort Payne Landscape Contractors · Pueblo West Landscape Contractors · Salem Landscape Contractors · San Pedro Landscape Contractors · Setauket-East Setauket Landscape Contractors · Seven Hills Landscape Contractors · Wayland Landscape Contractors · Silver Firs Landscape Contractors · Eastlake Landscape Contractorscole_robbie

PupillaCharitesOriginal Author

PupillaCharitesOriginal Author

grizzman

PupillaCharitesOriginal Author

grizzman

PupillaCharitesOriginal Author

grizzman

PupillaCharitesOriginal Author

grizzman

PupillaCharitesOriginal Author