New high tunnel in my future?

jrslick (North Central Kansas, Zone 5B)

10 years ago

Related Stories

HOME TECHIf ‘High-Def’ TV Isn’t High Enough, Maybe You Need Ultra-HD

The ultra-luxury next generation of TV, called Ultra-HD, is finally here. And so is the first content, if you know where to look

Full Story

PRODUCT PICKSGuest Picks: 19 Standouts From High Point Market

Let these metallic and nature-loving pieces inspire a spring decorating makeover and a bright outlook

Full Story

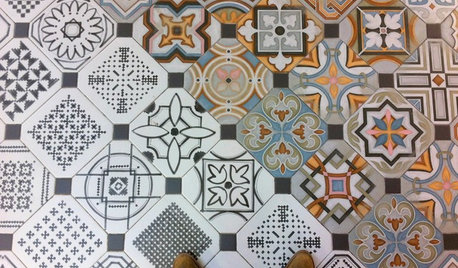

EVENTSTile Goes High Tech at Italy's Big Expo

Cutting-edge methods are creating tile looks from handmade to avant-garde, as seen as CERSAIE 2013

Full Story

THE ART OF ARCHITECTUREWorld of Design: Trees Bring Nature to a High-Rise in Milan

Discover ‘the most beautiful and innovative skyscraper in the world’ — the foliage-filled Bosco Verticale — and tour one of its apartments

Full Story

MOST POPULARHow High Should You Mount Your TV?

Today we look at an important question to consider when locating your television: How high should you set it?

Full Story

DREAM SPACESA Car Lover's Man Cave Kicks Into High-Luxury Gear

Fast cars, fine wines and a high-tech bathroom elevate this backyard outpost to the realm of dream space

Full Story

REMODELING GUIDESMaterial Choices: High Marks for Reinforced Concrete

Try poured-in-place construction for a wonderfully tactile, industrial look

Full Story

MUDROOMS4 High-Performing Mudroom Ideas

Looking for entryway ideas with plenty of storage? Here’s how to make hooks, cubbies and drawers look great

Full Story

LIGHTINGThe Lowdown on High-Efficiency LED Lighting

Learn about LED tapes, ropes, pucks and more to create a flexible and energy-efficient lighting design that looks great

Full Story

SMALL SPACESSmall Sleeping Nook, High Comfort

It's just big enough for a bed and a dresser, but this boy's 12-by-4 sleep space is comfy-cozy

Full Story

randy41_1

jrslick (North Central Kansas, Zone 5B)Original Author

Related Professionals

Derry Landscape Architects & Landscape Designers · Franconia Landscape Architects & Landscape Designers · River Forest Landscape Architects & Landscape Designers · Harvey Landscape Architects & Landscape Designers · Aberdeen Landscape Contractors · Apollo Beach Landscape Contractors · Arlington Landscape Contractors · Garland Landscape Contractors · Lady Lake Landscape Contractors · Lewisville Landscape Contractors · Longmont Landscape Contractors · Plantation Landscape Contractors · Whittier Landscape Contractors · North Hills Landscape Contractors · Swansea Solar Energy Systemsmyfamilysfarm

randy41_1

jrslick (North Central Kansas, Zone 5B)Original Author

jrslick (North Central Kansas, Zone 5B)Original Author

cole_robbie

jrslick (North Central Kansas, Zone 5B)Original Author

randy41_1

cole_robbie

jrslick (North Central Kansas, Zone 5B)Original Author

boulderbelt

trianglejohn

myfamilysfarm