Cages vs Concrete Wire?

jeff94519

16 years ago

Related Stories

DESIGN DICTIONARYGabion Wall

A wire cage filled with rock makes for a free-form wall solution

Full Story

LANDSCAPE DESIGNGarden Walls: Gabion Evolves From Functional to Fabulous

The permeable rock-, concrete- or glass-filled steel cages are showing up as retaining walls, planters, benches and more

Full Story

DECORATING GUIDESInspiring Materials: Metal Wire

Add the Open Look of Wire to Your Lighting, Furnishings and Decor

Full Story

CONCRETEWhy Concrete Wants to Crack

We look at the reasons concrete has a tendency to crack — and what you can do to help control it

Full Story

PATIOSLandscape Paving 101: Cast-in-Place Concrete

A construction standard, cast-in-place concrete can be used for a wide variety of project types

Full Story

INSPIRING GARDENSFrom Concrete Lot to Gracious Organic Garden in Seattle

Plants, pests and even weeds have a place in this landscape, which offers an edible bounty and a feast for the eyes

Full Story

LANDSCAPE DESIGN5 Ways to Make Your Concrete Patio More Attractive

These design ideas can liven up your paved outdoor space

Full Story

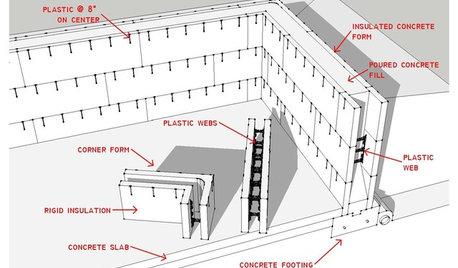

KNOW YOUR HOUSEKnow Your House: The Basics of Insulated Concrete Form Construction

Get peace and quiet inside and energy efficiency all around with this heavy-duty alternative to wood-frame construction

Full Story

TASTEMAKERSTastemakers: Talents Shine in New Lighting Designs

Inside Inspired Wire Studio, she says "Wouldn't it be cool if...?" and he makes it come to life

Full Story

MEDIA ROOMS5 Tips to Turn Your Basement into a Media Room

From wiring to gadgets to decor, a designer tips us off to the secrets for media room success

Full StoryMore Discussions

bigdaddyj

korney19

Related Professionals

Folsom Landscape Architects & Landscape Designers · Middle Island Landscape Architects & Landscape Designers · Waterbury Landscape Contractors · Aberdeen Landscape Contractors · Fair Lawn Landscape Contractors · Harvey Landscape Contractors · Kettering Landscape Contractors · Los Banos Landscape Contractors · Roswell Landscape Contractors · Streamwood Landscape Contractors · Jacinto City General Contractors · Meadville General Contractors · Murrysville General Contractors · Winton General Contractors · Benton Decks, Patios & Outdoor Enclosuresanney

korney19

tomstrees

deepsand

gonefishin

deepsand

gonefishin

korney19

frugal_gary

korney19

gonefishin

vall3fam

doof

jeff94519Original Author

korney19

john90808

gonefishin

digdirt2

dwmcclain

bigdaddyj

vgautam

bigdaddyj

bigtomato

foose4string

dave1mn2

tazmo

tbt3

kwik1

tomstrees

tomstrees

bootster

jsvand5

bigdaddyj

macheske

bootster

lakeshorenc

rockrick

brandyray

thepodpiper

macheske

thepodpiper

tomakers

plant-one-on-me

dave1mn2

lightt

dave1mn2

elkwc

horse_chick