john deere 318 won't start

markwettig

10 years ago

Related Stories

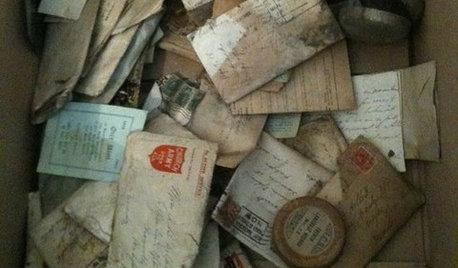

REMODELING GUIDESYou Won't Believe What These Homeowners Found in Their Walls

From the banal to the downright bizarre, these uncovered artifacts may get you wondering what may be hidden in your own home

Full Story

TREES7 Deer-Resistant Flowering Trees to Plant this Fall

If you live in a neighborhood with roaming deer, consider these beautiful trees that won't tempt hungry guests

Full Story

FALL GARDENING9 Deer-Resistant Flowering Shrubs to Plant This Fall

These exquisite shrubs will attract your attention but won’t tempt the deer that roam your neighborhood at night

Full Story

DECLUTTERING5 Ways to Jump-Start a Whole-House Decluttering Effort

If the piles of paperwork and jampacked closets have you feeling like a deer in the headlights, take a deep breath and a baby step

Full Story

CONTRACTOR TIPS10 Things to Discuss With Your Contractor Before Work Starts

Have a meeting a week before hammers and shovels fly to make sure everyone’s on the same page

Full Story

GARDENING GUIDESOh, Deer! 10 Native Flowers That Stand Up to the Herds

Keeping a garden amid hungry deer can be hard, but these plants should fare well

Full Story

ARCHITECTURESee the Daring Experimentalist Who Won 2013's Pritzker Prize

Architecture's highest honor goes to someone with a diverse and complex body of work and a never-satisfied mind-set

Full Story

FENCES AND GATESA Deer Fence Can Be Decorative as Well as Protective

You need a monster-size fence to shelter your garden from deer, but it doesn’t have to look like a monstrosity

Full Story

MOST POPULARHow to Start a Cool-Season Vegetable Garden

Late summer and late winter are good times to plan and plant cool-season crops like salad greens, spinach, beets, carrots and peas

Full Story

GARDENING FOR BUTTERFLIESA Quick-Start Guide to Bird-Watching for Fun and Learning

Set out some seed and grab your field guide. Bird-watching is an easy, entertaining and educational activity for the whole family

Full Story

Sponsored

bill_kapaun

markwettigOriginal Author

Related Professionals

Fort Lee Landscape Architects & Landscape Designers · Jennings Landscape Architects & Landscape Designers · Mitchellville Landscape Architects & Landscape Designers · Forest City Landscape Architects & Landscape Designers · Washington Landscape Architects & Landscape Designers · Milford Landscape Contractors · Annandale Landscape Contractors · Galveston Landscape Contractors · Ramsey Landscape Contractors · Tavares Landscape Contractors · Wichita Window Contractors · Plainview Window Contractors · Tucker Window Contractors · West Springfield Window Contractors · Hialeah Gardens Window Contractorsbill_kapaun

markwettigOriginal Author

bill_kapaun

markwettigOriginal Author

bill_kapaun

markwettigOriginal Author

bill_kapaun

markwettigOriginal Author

Bob Yingling

Bob Yingling